COOLING

MODULAIR SPLIT AC UNIT

HI AIR KOREA(HAK) MODULAIR SPLIT AC UNIT equipment is specifically designed for onshore and offshore containerized module applications.

Standard capacities up to 14 kW(4 tons) for split units. Larger capacities are available on request.

Suitable for cooling-only applications at typical ambient conditions of 15 ~ 40 °C.

TYPICAL INSTALLATIONS

- Drilling Control Cabins

- ROV Operator Cabins

- Local Equipment Rooms

- Instrumentation Rooms

- Crane Cabins

- Muster Areas

- Laboratories

- Enclosed Walkways and Egress

Truly a customizable unit for every application!

-

FEATURES

MODULAIR SPLIT AIR CONDITIONING UNIT

The split unit range has three standard capacities of 7 kW(2 tons), 9 kW(2.5 tons) and 14 kW(4 tons). Engineered to operate across a range of standard power supplies from 200-480V, 1~3 Phase, 50~60 Hz. Air Cooled Condensing Unit casings are manufactured in 316L stainless steel as standard. Internal Evaporator units have options for stainless steel or proprietary finishes. Additional kW capacities, power supplies and evaporator style units as well as some equipment suitable for Zone 1 can be provided on request.

STANDARD UNIT TYPES are provided as follows

- TYPE A : All equipment suitable for safe area use

- TYPE B : Zone 2 Air Cooled Condenser. Safe area Evaporator and Control Panel c/w Compressor

- TYPE C : Zone 2 Air Cooled Condensing Unit c/w Compressor. Safe area Evaporator and Control Panel

- TYPE D : Zone 2 Air Cooled Condensing Unit c/w Compressor and Ex’d’ Control Panel. Safe area Evaporator

The range of split units are provided with the following controls and functionality as standards

- Room temperature controller

- Evaporator coil frost protection

- Reversing valve(heat pump models only)

- High and low pressure safety switches

- Fan cycling control

- Voltage selector switch

- Phase sequence

- Monitoring

Additional control functions can be included on an engineered-to-order basis.

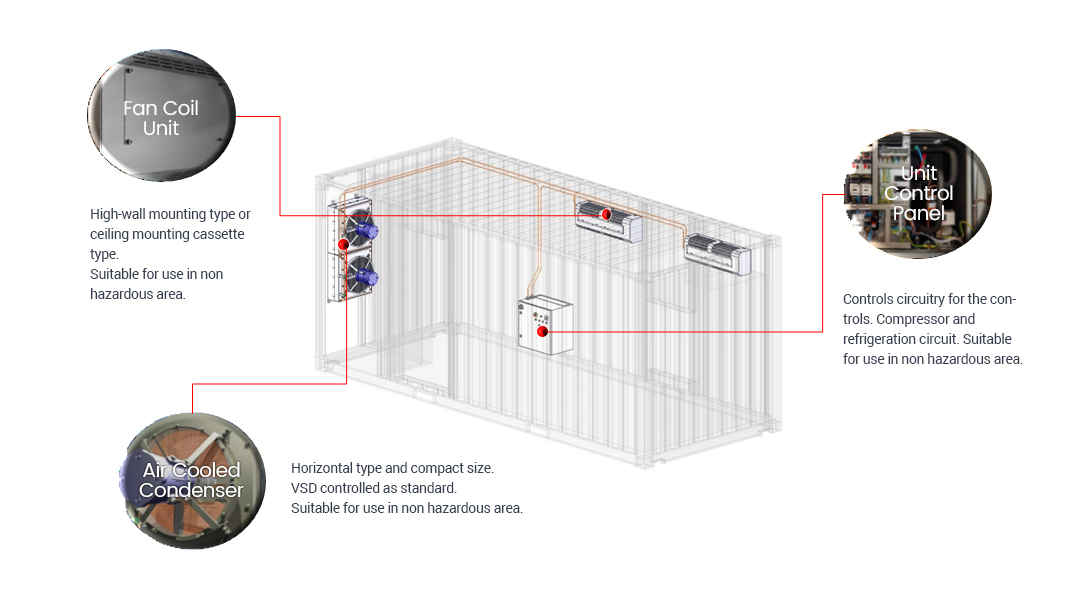

TYPE A, SAFE AREA USE

Standard Control Panel and Evaporator Unit suitable for mounting internally with the Condensing unit fabricated from 316L Stainless Steel suitable for mounting in an external Marine Saline environment.

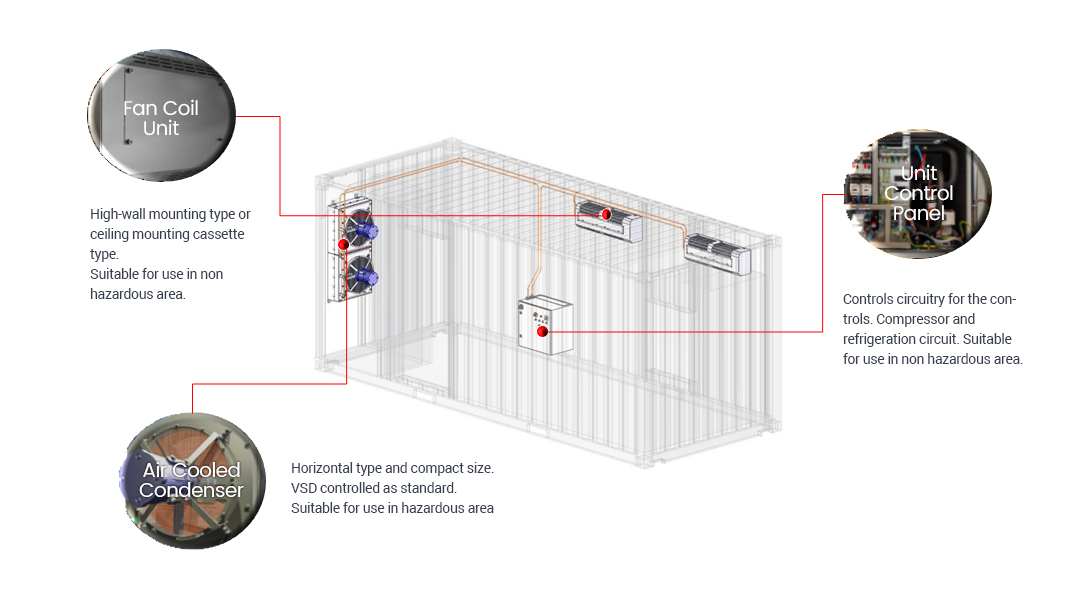

TYPE B, HAZARDOUS AREA RATED USE

Indoor equipment includes Safe Area Control Panel c/w Compressor and Evaporator Units. Outdoor equipment is rated for use in a hazardous area and includes a Condensing unit fabricated from 316L Stainless Steel suitable for mounting in an external Marine Saline environment.

TYPE C, HAZARDOUS AREA RATED USE

Indoor equipment includes a small Safe Area Control Panel and Evaporator Units. Outdoor equipment is rated for use in a hazardous area and includes a Condenser c/w Compressor mounted into a 316L Stainless Steel casing suitable for mounting in an external Marine Saline environment.

TYPE D, HAZARDOUS AREA RATED USE

Where Indoor space is at a premium and can only fit Evaporator Units. Outdoor equipment is rated for use in a hazardous area and includes Control Panel, a Condenser c/w Compressor mounted into a 316L Stainless Steel casing suitable for mounting in an external Marine Saline environment.

DESIGN

- Customized for onshore & offshore applications

- Available power supply in 200~480Vac, 50~60Hz, 1~3phase

CONSTRUCTION(aside from those mentioned above)

- High quality integrated components for maximum reliability

MAINTENANCE

- Easy installation and maintenance

-

OPTIONS

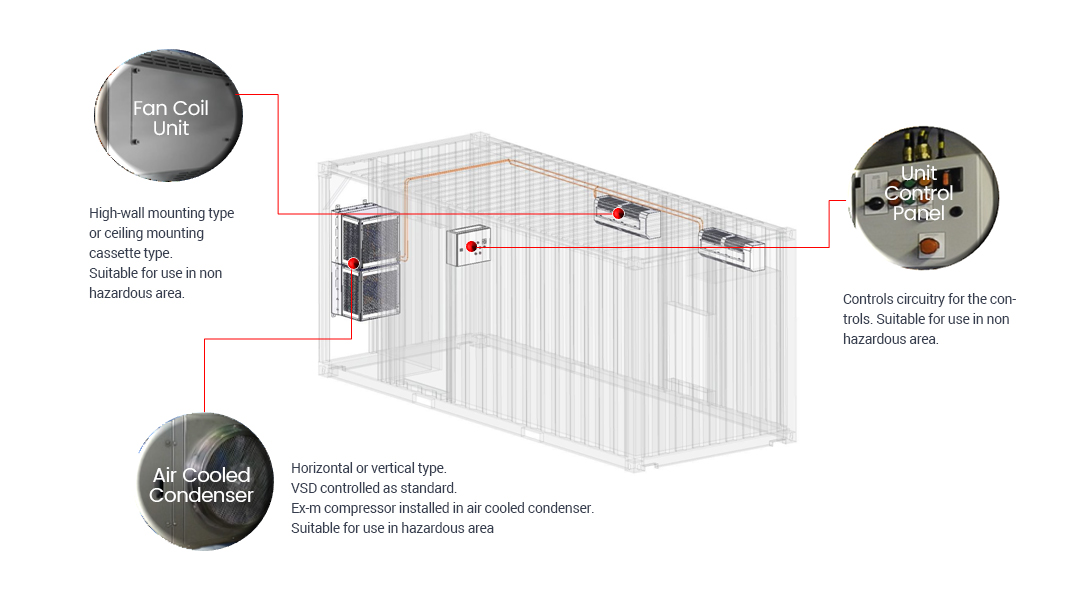

FAN COIL UNIT

- SS316L Casing(Type A, B, C & D)

AIR COOLED CONDENSING UNIT

- Spark proof fans(Type B, C & D only)

- Explosion proof motors(Type B, C & D only)

COMPRESSOR

- Explosion proof Compressor(Type C & D only)

UNIT CONTROL PANEL

- Explosion proof Enclosure(Type D only)

OTHER AVAILABLE OPTIONS

- Running at Low Ambient Temperature

- Running at High Ambient Temperature

- Running for both Cooling & Heating(Reverse Cycle)

ADDITIONAL COMPONENTS & CERTIFICATION

- ATEX, IECEx certification of components such as compressor, air cooled condensing unit and unit control panel

-

SELECTIONS

Configuration Model Code Description Equipment Type A Type A - Safe area Equipment Only : Air Cooled Condenser Unit, Compressor, Control Panel & Evaporator

B Type B - Zone Rated Equipment : Air Cooled Condenser Unit

- Safe Area Equipment : Evaporator, Compressor & Control Panel

C Type C - Zone Rated Equipment : Air Cooled Condenser Unit & Compressor

- Safe Area Equipment : Evaporator & Control Panel

D Type D - Zone Rated Equipment : Air Cooled Condenser Unit, Compressor & Ex'd Control Panel

- Safe Area Equipment : Evaporator

Nominal Cooling Capacity 7 7 kW 9 9 kW 14 14 kW SB Special Build Package Function CO Cooling Only CH Cooling & Heating Refrigerant Type R4 R-407C R1 R-134a S1 Special Zone Rating NH Non-Hazardous Safe Area A3 Hazardous Rated ATEX A2 Hazardous Rated IECEx SB Special Power Supply

(Vac, Ph, Hz)No. 50 Hz 60 Hz 1 200 / 1 208 - 230 / 1 2 200 - 2 / 3 200 - 230 / 3 3 - 380 / 3 4 380 - 420 / 3 460 / 3 5 200 / 3 208 - 230 / 3 6 220 - 240 / 1 265 / 1 7 220 - 240 / 1 - 8 380 - 420 / 3 - 9 380 / 3 - 10 220 / 1 - Casing Material CE Condenser & Evaporator ANSI 316L SS CS Condenser ANSI 316L SS with STD Evaporator MS Manufacturers Standard Condenser Coil CC Copper Tubes/Copper Fins CT Copper Tubes/Copper Fins, Heresite + UV Coating ST Special Treatment Evaporator Type W Wall Mount C Ceiling Mount S Special - DOCUMENTS