AIR HANDLING

AIR CLEANING UNIT

(FOR NUCLEAR POWER PLANT)

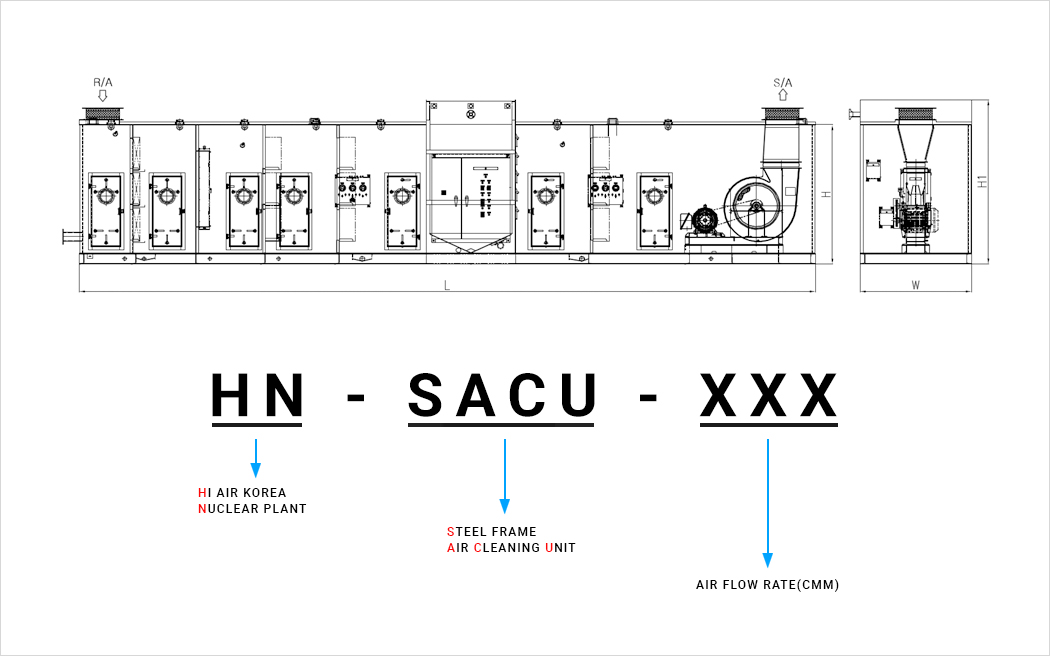

HI AIR KOREA(HAK) AIR CLEANING UNIT is designed to optimally operate in some of the harsh conditions in Nuclear Power Plants.

HAK AIR CLEANING UNIT is specifically constructed to provide clean air by removing the dust with radioactivity in Nuclear Power Plant considering size, efficiency, reliability and maintainability.

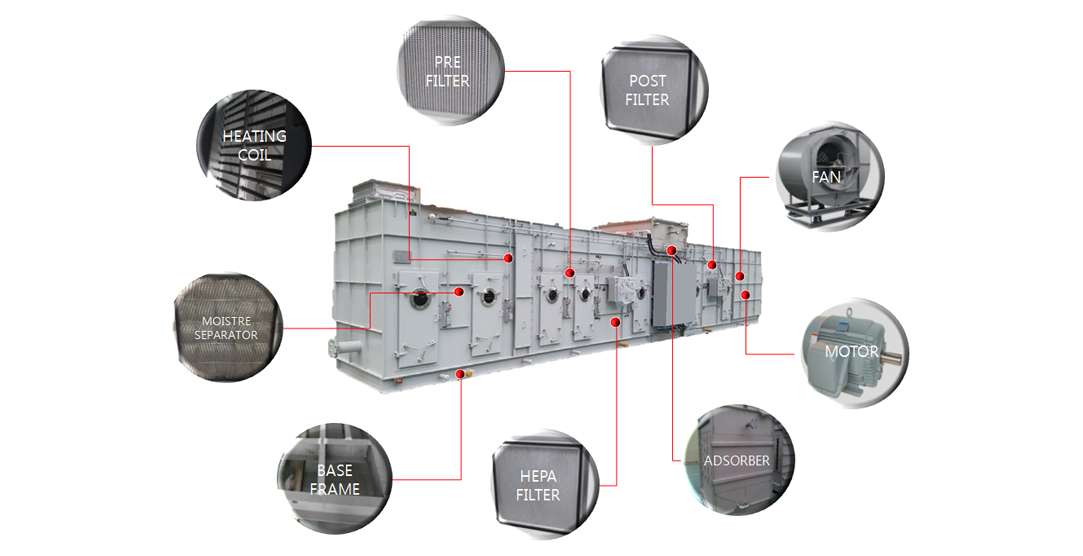

The unit is composed of moisture separator, heating coil, pre filter, HEPA filter, adsorber, post filter and fan/motor.

Truly a customizable unit for every application!

- FEATURES

CASING

- Housings are made of painted carbon steel of 7-gauge minimum thickness

- Each section shall have enough strength to meet the specified design loading including seismic acceleration

BASE FRAME

- The base frame is made of carbon steel

- Rigid enough to support all components during shipping, lifting and operation

- Spaces between the frame are also considered for installation of drain piping

MOISTURE SEPARATOR

- Moisture separators are designed, constructed, and tested in accordance with Section FA of ASME AG-1 and ASME N509, Paragraph 5.4

- Removing at least 99 % by weight of the entrained moisture in an airstream containing approximately 1.5 to 2 lb of entrained water per 1,000 cu ft and by count of 5 of 10 μm diameter droplets

ELECTRIC HEATING COIL

- Electric air heaters are designed, constructed, and tested in accordance with Section CA of ASME AG-1 and ASME N509, Paragraph 5.5

- Elements have 80 % nickel and 20 % chromium resistance wire centered in a metal sheath and insulated from the sheath by magnesium-oxide refractory

- Heating coils are rated for operating at 480Vac, 60Hz, 3-phase

PRE FILTER

- The pre filters are designed, constructed, and tested in accordance with Section FB of ASME AG-1 and ASME N509, Paragraph 5.3

- The pre filters average atmospheric dust spot efficiency are at least 90 %, when tested in accordance with ASHRAE 52.1 or ASHRAE 52.2

- The filter is replaceable, extended media, dry-type

- Pre filter is UL 900 classified

HEPA FILTER AND POST FILTER

- The HEPA filters and post filters are of same construction and designed, constructed, and tested in accordance with Section FC of ASME AG-1 and ASME N509, Paragraph 5.3

- HEPA filter and post filters shall satisfy the requirements of UL-586

- HEPA filter and post filters are 24 x 24 x 11 1/2(nominal size) inches with a minimum rated airflow of 1,500 scfm(2,000 scfm recommended) and clean pressure drop of less than 1.3 in. WG

ADSORBER

- Adsorber is designed, constructed and tested in accordance with Section FE of ASME AG-1, Paragraph 5.2

- Adsorber banks are arranged in accordance with Section HA of ASME AG-1 and Section 5.0 of ASME N509

- Adsorber cells are Type III and meet the requirements of Section FE of ASME AG-1, ASME N509, Paragraph 5.2

- Adsorber cells meet the requirements of USNRC RG 1.140

- Adsorbent is made of activated carbon and to be qualified in accordance with Section FF of ASME AG-1

FAN

- Centrifugal type

- Double width double inlet

- V-belt driven, complete with fan belt guard

MOTOR

- Premium efficiency

- Cast iron casing

- IP 54/55 protection

- Power supply : 480Vac, 60Hz, 3-phase

- CAPACITIES

MODEL NO. AIR FLOW RATE MOTOR HEATING

CAPACITYADSORBER EXTERNAL

STATIC

PRESSUREDIMENSION WEIGHT BED Q'TY BED

THICKNESSm3/min kW kW EA inch Pa W (mm) H (mm) H1 (mm) L (mm) kg HN-SACU-042 42 7.5 7 4 6 1,500 1,400 1,690 1,895 11,180 7,750 HN-SACU-113 113 22 15 8 6 1,800 1650 1,780 1,970 12,450 10,815 HN-SACU-142 142 22 25 8 6 1,300 1,650 1,910 2,270 12,450 10,815 HN-SACU-227 227 30 17 8 6 1,000 1,650 2,390 2,890 12,450 13,350 HN-SACU-255 255 30 26 8 6 1,000 2,060 2,580 3,040 13,620 14,570 HN-SACU-419 419 93.3 43 14 4 3,300 2,720 2,580 2,970 13,060 18,820 HN-SACU-699 699 93.3 70 16 4 2,500 3,060 3,130 3,690 13,540 28,840